CYSG-800M/WB

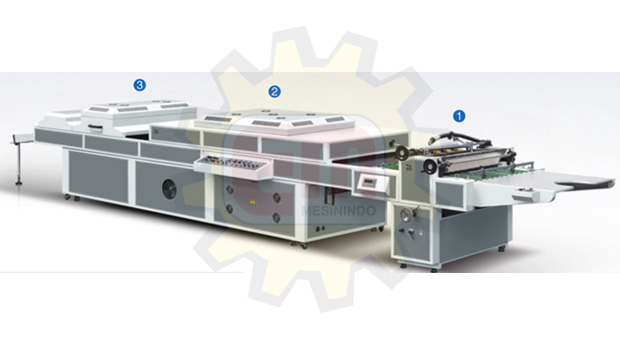

CYSG-800M/WB Semi-automatic Water-based Coating Machine

CYSG-800M/WB Semi-automatic Water-based Coating Machine.

Equipment features and functions:

- There are suction and wheel pressure under the paper feeding table.

- Main engine wallboard cast iron structure, 6 paper inlet belts and 2 paper outlet belts with suction underneath.

- The coating roller adopts the rolling extrusion oil and reverse oil (the latter is used when making dumb oil and tissue paper).

- The paper feeding position is equipped with optical fiber probe for accurate memory of paper feeding.

- The coating cots are equipped with optical fiber, in order to protect the cots, the paper will automatically stop.

- Thin paper USES air knife to blow qigong energy, optical fiber and encoder to control solenoid valve.

- The oven is equipped with a standard of 6 meters (customized according to customer requirements). The oven heating lid will automatically rise and fall when the machine is shut down or started up.

- The mesh belt is high temperature resistant and automatic edge correction.

- Part of the paper receiving machine: 6 strips of paper feeding belt (with suction) are pressed into corrugated form with the upper pressing wheel to improve the paper receiving effect, and there is qigong blowing energy below.

- Diversified instrument display. (Can display presets, cumulative count; Meter, linear speed, efficiency, etc.)

|

Technical Specifications |

|

|

Model |

CYSG-800M/WB |

|

Type |

Paper main machine (reverse with wind knife), drying path, paper |

|

Speed |

5-30M/min |

|

Max. paper size |

750MM |

|

Dryer way |

IR/UV |

|

IR Drying Tunnel |

IR light 30-100? power 1.5KW/18pcs |

|

IR Fan |

8pcs |

|

IR Power |

27KW |

|

Total Power |

48kw |

|

Weight |

4000kg |

|

Dimension |

8500*1500*1350mm |