DF16 DF18 DF20 DF22 DF25

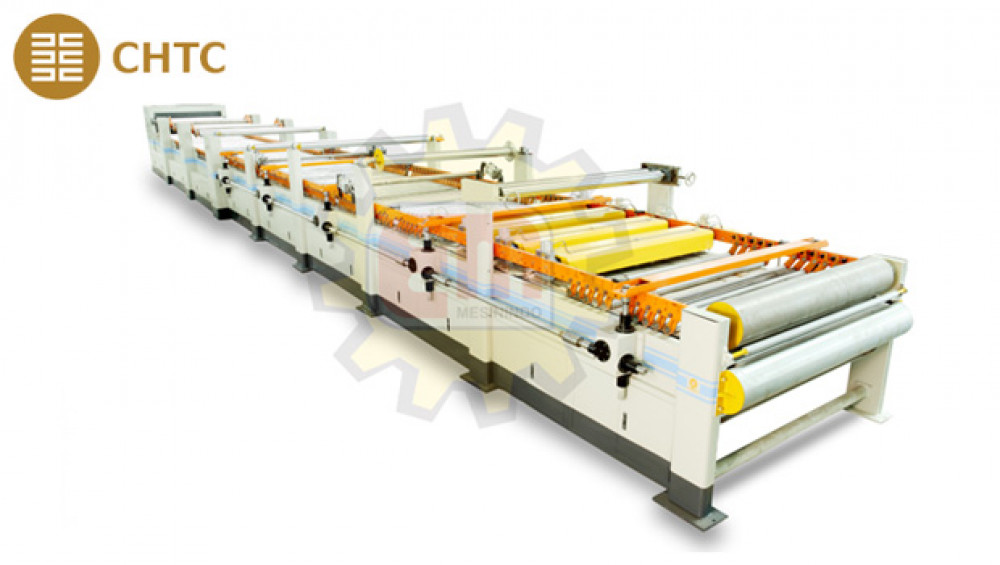

Double Facer Paper Corrugating Machine

Double facer is attached by machine sizing paste into the hotplate heating after molding and then cooled by cooling to form the paper board. The whole machine girder of double –sided machine adopted heavy type channel steel system, good rigidity, stable system, aesthetic appearance. Designed to canvass belt on the left and right device for automatic correction, making sure the canvass belt stable in working and the air pressure automatic control tightness.

- The heating source of hotplate is steam, the temperature of every part is adjusted the valves which depend on the layers of

- corrugated paperboard and the speed.

- Hydraulic pressure for up and down, subsection pressure according to the layers of corrugated paperboard. Keeping suitable pressure is easy for the paperboard to form.

- Both the upper and lower canvas belts are provided with automatic deviation adjusting mechanisms.

- Overhead canvas belt supporting type, with two sets of upper canvas belt tensioning mechanisms.

- The operating surfaces of the heating plates are ground, and plated with hard chromium, and the heating plates meet the China national standard for Class 1 pressure vessels, all heating plates are attached with pressure vessel inspection certificate, etc.

- The steam pipes are arranged reasonably to realize grouping temperature adjustment for heating plates.

- With deviation correction device for belt mazy interval channel in heating plates make heating even.

| Technical Spesification | |

|---|---|

| Model | DF16/DF18/DF20/DF22/DF25 |

| Machine speed | 230m/min |

| Effective brand | 1400/1600/2800/2000/2200/2500 |

| Heating source | Steam |

| Heating plates | 15,18,20,22 |