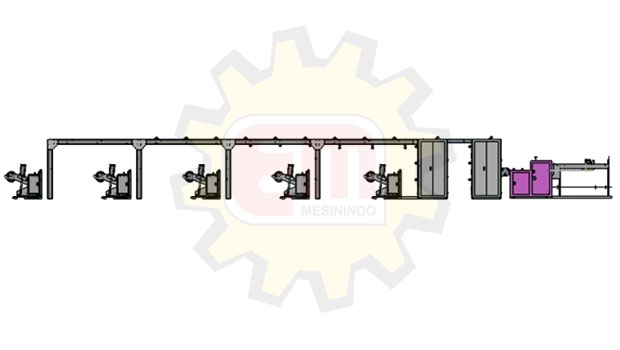

HQJ-1400B

HQJ-1400B Reel Cutting Machinery

Performance and characteristic:

- This paper cutting machines is suitable for cutting big rolling packaging materials such as paper, paper-plastic, multi-color laminated material, etc.

- It adopts servo motor for controlling constant-length cutting.

- It adopts pneumatic, photoelectric sensor for controlling transmission system, with photo, electric, gas together,

- It has the functions of easy operation, high precision, good stability, low noise.

- This machine has the functions of the frequency converter timing device, automatic counting, stop working by alarm and tension adjustment by magnetic powder or manual with friction unit.

Features:

1. Unwinding unit

Pneumatic airshaft paper shaft 1300kg

- Maximum paper roll diameter: 1400mm (55”)

- Maximum paper roll width: 1400mm

- Minimum paper roll width: 300mm (13.7”)

- Paper roll inner diameter: 3 inches inside diameter of paper roll

- Air cylinder drive unit

- Paper guiding roll and shaft

- Auto tension control

- Unwinding tension using magnetic powder control system (20 kg)

- Automatic EPC correction system

2. Main machine part

- Shaft: Trough steel and high-quality steel plate structure in 10mm thickness

- Main machine adopts frequency control (3 KW)

3. Traction device

- Structure style: active traction and passive press fasten style

- Based seat is casting structure (1set)

- Traction roller is rubber roller (Spec: 12unitφ85×1450mm)

- Press fasten style: controlled by pneumatic

- Press fasten cylinder: (10unitφ40×20mm)

- Transmission guide roller: aluminum guide roller (Spe. 30unitφ74×1450mm)

- Traction motor adopts servo motor 3kw, Drive in-phase fix the length

- Length can be adjustable by micro-computer

- Traction adopts frequency control (1.5 KW 5set)

4. Material delivery structure

- Adopt servo motor control system Inovance brand

- Drive style: drove by main motor and traction through active roller

- Transmission: adopts triangle belt and belt wheel together structure

- Material-delivery adopts floating backrest structure for buffer action to keep material

- Floating upper and lower tension adopts pneumatic traction Cylinder

- Floating guide roller adopts aluminum guide roller

- Whole material-delivery structure will be controlled by displacement sensor

5. Cutting Unit

- Cutting style: fix well the lower cutter and cut actively by upper cutter

- Cutter holder: adopts casting heavy style structure

- Lubricating oil can be recycled using

- Both upper and lower cutters adopt bar style imported steel cutter

- Cutting blade (Spec.Thickness×width×Length: 15×80×1450mm)

- Cutter position can be adjustable by hand

- Active transmission style: main motor transmission equipped with derailleur enable centrifugal wheel joined with connecting pole to run cutter reciprocating

6. Paper sheet collection

- Automatic sheet collection

- Lifting motor adopts 1.5kw frequency converter adjusting speed

- Lifting automatic with sensor inspecting, auto lifting down

- Right and left stacking adopts DC motor, the width stacking can be adjustable

7. Electrical control part (PLC Control)

- The whole machine adopts PLC control

- The electronic original adopts the French "Schneider" brand

- The system designed with Inovance

|

Technical Specifications |

|

|

Model |

HQJ-1400B |

|

Max. width of cutting |

1400mm |

|

Cutting thickness |

17-500 grams (0.06~0.50mm) (depending on different materials) |

|

Max diameter of material (shaftless) |

Φ1400mm (Maximum 1300kg) |

|

Length of cutting |

30-1200mm |

|

Speed |

160 times/min |

|

Precision of fixed length |

±0.2mm |

|

Total Power |

9.5 kw (380V 50 HZ) |

|

Weight (approx.) |

8600KG |

|

Overall dimension (LxWxH) |

17000mm×2200mm×2200mm |