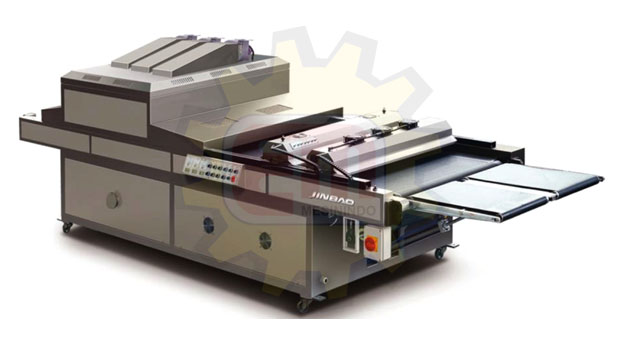

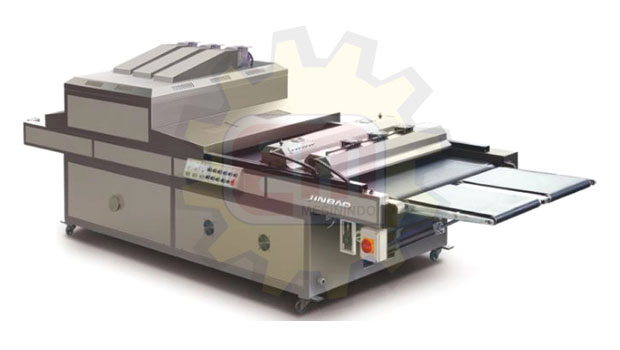

JB-800S / 1050S

JB-800S / 1050S Full Automatic Stacker

JB-800S/1050S Full automatic stacker can combine with full-automatic cylinder type screen press and all kinds of dryer together to collect the paper and make them in order automatically.

- The whole machine is controlled by PLC, collecting printing substrate and making the paper in order automatically.

- Photoelectricity monitoring, two sides of baffles run when the paper come into the plate.

- Paper conveying system is controlled by inverter with stepless speed regulation and conveyor belt guide the idler wheel to feed the paper.

- Pneumatical elements control the jogger action, which avoid paper to be broken or other damage.

- Following all kinds of paper size, paper jogging device can be adjusted from back, left and right easily and conveniently.

- Induction sensor make the stacking board down automatically and keep paper collect smoothly.

- Paper stacker has limitation safety mechanism at up and down position to avoid the machine from damaged.

- Paper jam and paper pile height supervision and make the printing press stop in-line.

- Connected with the printing part which can control the printing part's running.

- Paper counting function.

|

Technical Specifications |

||

|

Model |

JB-800S |

JB-1050S |

|

Max. Paper size |

800×600mm |

1100×750mm |

|

Min. Paper size |

350×270mm |

560×350mm |

|

Max. Pile height |

700mm |

700mm |

|

Top speed |

4200pcs/h |

4200pcs/h |

|

Installed power |

3P 380V 50Hz 0.92KW |

3P 380V 50Hz 0.92KW |

|

Total weight |

600kg |

650kg |

|

Overall size |

1900×1750×2500mm |

2000×2050×2500mm |