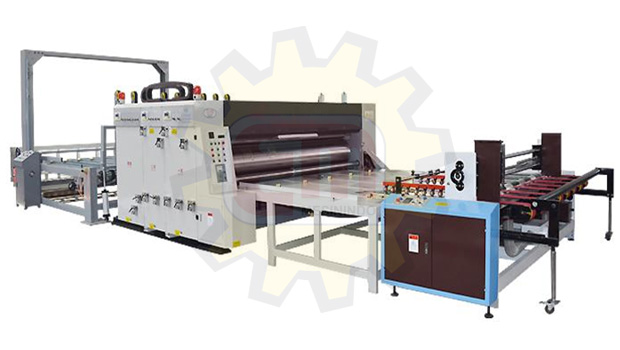

YSK-0920

YSK-0920 4 Color Printing Machine

Main function:

This machine adopts prefab chain paper feed, leaflet manual feeding, made convenient, with high efficiency, save energy, safety etc.

- The machine uses 360 degrees Planetary motor phase adjustment (microcomputer digital phase meter) can directly input digital, adjust faster, higher accuracy.

- Fission the use of electric points close, pneumatic lock, pneumatic brake device, ensure every time points after a good fit, the operation is convenient and quick.

- Distributing device, ink formed roller with automatic idle function, make when machine stop ink won't dry.

- Transmission gear, 45# steel, helical gear after grinding and induction hardening process (precision more than six) from finishing some locations adopt keyless devices, with no gaps, higher cutting accuracy.

- Transmission roller: all the transmission roller for the quality of 45# steel, by quenching and tempering, grinding, balance correction, hard chrome plated.

- Lubrication device: this machine adopts the automatic (mechanical pump) spray type circulation lubrication device, automatic spray oil, inking amount evenly, each group and circulation, and improve the service life of the gear and the precision of the chromatically.

- Electrical appliances: the main parts imported schneider, Siemens, and other well-known manufacturers, its stability greatly increased.

- Anilox roller mesh can option 180-250mesh (optional)

Printing department (Optional 1-4 color printing unit)

1. Printing roller

- The outer diameter ?290mm, (including the plate of the outer diameter is: ?304.4mm).

- The steel tube surface grinding, hard chrome plating

- Computer dynamic balancing correction, smooth operation

- Ratchet fixed plate shaft. (optional)

- Change plate slot, suitable for 9mm plate bar. (optional)

- Loading and unloading printing plate, foot switch electric control positive and negative rotation. (optional)

2. The printing press roller

- The outer diameter: 156mm

- Steel pipe surface grinding, hard chromium plating.

- Balance correction, smooth operation.

3. Feeder paper up and down roller

- Up roller, the outer diameter of: ? 86 mm, thick wall steel pipe, with two feeder paper rollers

- Down roller, the outer diameter: ? 156 mm, thick wall steel pipe, surface grinding, hard chromium plating.

4. Steel anilox roller

- The outer diameter: ?175.4mm (mesh number: 180-250, mesh optional)

- Steel pipe surface grinding, suppress anilox, hard chromium plating

- do balance correction, smooth operation, network is consistent, uniform inking .

- Anilox roller wedge type overrunning clutch, distributing, wash ink is convenient swift

5. Rubber roller:

- Outer diameter is: ?175.4mm.

- Steel pipe surface parcel wear-resisting rubber, and do correction balance.

- Rubber roller middle high is the special grinding, ink transfer effect is good

- Rubber hardness is: 60-65 degrees.

6. Phase adjustment mechanism

- Planetary gear structure

- Print phase electric digital 360-degree adjustment, (operation, stop adjustable).

- Manually adjust the horizontal position, adjust the distance ± 10mm.

7. Ink circulation

- Pneumatic diaphragm pump, ink stability, convenient operation and maintenance

- Ink filter, filtering impurities

8. Printing phase fixing device

- Cylinder type brake device

- When the machine separate adjustment phase, the brake institutions limit the machine running, keeping the original gear fixed point position.

9. Oil supply device

- Mechanical oil pump (double oil pump supply cycle)

- Cycle oil supply, gear ink volume uniform, each oil level balance

Slotting unit

1. Pressure line device

- Shaft diameter is ?86, surface grinding, hard chrome plating, smooth movement.

- Balance correction, smooth operation.

- Crimping wheel uses French Martin technology, with soft pressure, straight line and not explosive.

- Pressure roller clearance dial manual adjustment, adjustment range 0-12mm.

2. Slotted knife seat traverse adjustment mechanism

- Shaft diameter: ?124mm, surface grinding, hard chrome plating, smooth movement.

- Slotted knife width: 7mm.

- Alloy steel heat-treated grinding tooth slotted knife, hardness and toughness are superb.

- Alloy steel heat-treated grinding trimming knife, sharp knife edge, high precision.

3. Slotted phase adjustment mechanism

- Planetary gear mechanism.

- Slot phase electric digital 360-degree adjustment, (operation, stop adjustable).

- Synchronous box height adjust: four knives moving at the same time, easy to operate, fast, and higher accuracy.

4. Manual linkage instruction

- It refers to the upper knife, the lower knife, the upper pressure line theory, the lower pressure roller, and synchronous movement at the same time, which is convenient for the customer to operate and fast, thereby improving work efficiency and saving production cost.

- Linkage guide rail: GCr15 steel, linear axis positioning, easy to move when adjusting the size, high straightness.

- The linkage positioning fork is used, and the positioning fork adopts high-quality copper block, which has small wear and high precision.

- this machine can match the punching and the clasp hands device. (optional), can chose electric adjust blade, electric carton height gasket, thus improve the service life.

|

Technical Specifications |

|

|

Model |

YSK-0920 |

|

Max sheet size |

2100×900mm |

|

Max printing area |

2000×900mm |

|

Min printing size |

300×600mm |

|

Work speed |

0-60 film/min |

|

Plate thickness |

4-6mm |

|

Roller diameter |

?304.4mm including printing plate pad |

|

Slotting width* depth |

7×220mm |

|

Phase adjust |

Electric 360° |

|

Main motor |

7.5kw |

|

Main motor |

9.5kw |

|

Tinted precision |

±0.5mm |

|

Slotting precision |

±1.5mm |

|

Weight |

9T |

|

Overall size (printing machine) |

7500×3300×1900mm |

|

Overall size (printing machine+stacking machine) |

17000*3300*3000mm |