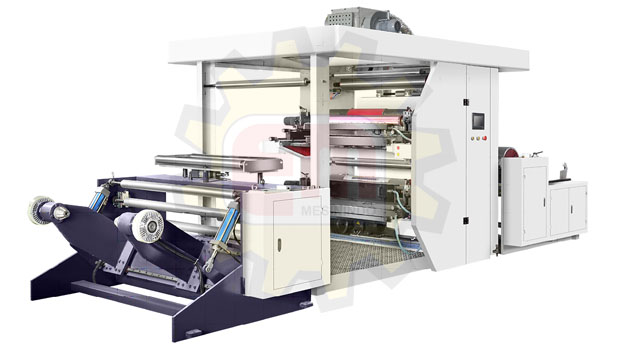

YT-21300

YT-21300 Flexo Printing Machine

FEATURES:

CONTROL PART

- Main motor frequency control

- PLC touch screen control the whole machine

- Reduce motor separate

UNWINDING PART

- Single workstation

- Hydraulic clamp, hydraulic lift the material, hydraulic control the unwinding material width, it can adjust left and right movement.

- Magnetic powder brake auto tension control

- Auto web guide

PRINTING PART

- Pneumatic lifting and lowing printing plate cylinders auto lifting plate cylinder when the machine is stopped. After that can run ink automatically. When the machine is opening, it will make alarm to start the auto lowering plate printing cylinder.

- Inking with ceramic anilox with chambered doctor blade (2 pcs)

- The synchronous motor points 360-degree planetary gear box continuously and longitudinally, and the accuracy is as high as <0.15mm.

- ±20mm transverse register

- Adjust inking press and printing pressure press by manual

DRYING PART

Adopt with external heating pipe, temperature display, electric current control, centrifugal blower brings the wind

REWINDING PART

- Back-to-back rewinding

- Pneumatic tension control

- 3-inch air shaft

- Hydraulic lowering the material

|

Technical Specifications |

|

|

Model |

YT-21300 |

|

Max. Printing material width |

1300mm |

|

Max. Printing width |

1260mm |

|

Max. Unwinding diameter |

1300mm |

|

Max. Rewinding diameter |

1300mm |

|

Printing length range |

228-1000mm |

|

Printing speed |

5-100m?min |

|

Register precision |

≤±0.15mm |

|

Thickness of plate (including the thickness of double sides glue? |

Customer request |