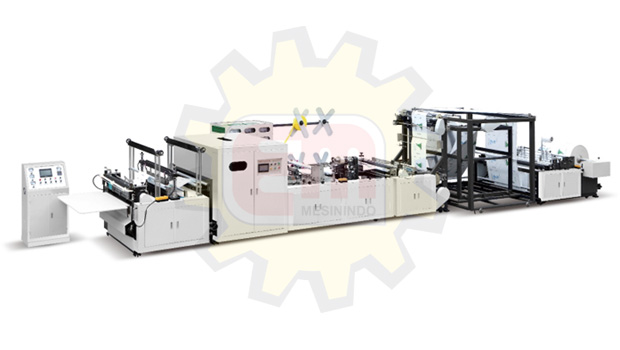

ZB-320-4

Colors Flexo Printing Machine

ZB-320-4 Colors Flexo Printing Machine. The main motor adopts imported converter to govern in a steepless way. Adopt ceramic mesh distributor roller, which is characterized by durability , wear resistance, and corrosion resistance, The doctors can be Used, which is more efficient for reducing the times for changing in order to increase the production efficiency.

- The main motor adopts imported converter to govern in a steepless way.

- Feeding and discharging are controlled through magnetic powder brake and clutch (Japanese Mitsubishi aut tension controller).

- Unhindered system is controlled by auto rectify sensor.

- Adopt ceramic mesh distributor roller, which is characterized by durability , wear resistance, and corrosion resistance, The doctors can be Used, which is more efficient for reducing the times for changing in order to increase the production efficiency.

- The printing unit can register in 360degrees. Each printing unit can independently gear and loosen to have the units continue printing.

- The printing units are all equipped with a group of infrared dryers respectively.

- Each IR dryer device of printing unit can interchange of UV dryer device.

- The roofing device is adopted with a group of infrared dryers respectively.

- The inking roller can automatically fall off at stoppage and transfer at low speed in order to keep the ink from being dry and solid.

- The roll feeding, printing, auto infrared drying. Laminating and rolling can be processed in one processing. Lt is characterized by wide application, non-population of printing ink and fast drying, quick printing. So it is an ideal printing machine for the commercial bill to print high Graded free adhesive trademark.

- The scraping blade is used to improve ink filling, and at the same time it can prevent splashing ink hurting working people.

- The camera with display can show people the image of the sticker.

| Technical Spesification | |

|---|---|

| Model | ZB-320-4 |

| Web width | 330 mm |

| Print width | 320 mm |

| Unwinding and rewinding | 600 mm |

| Press speed max | 60m/min |

| gear Pitch | 1/8"(3.175 mm) |

| Min. Max repeat | 7" - 13.5" |

| Voltage | 3 phase 380V, 50 Hz |

| Diameter of air shafts | 76 mm |

| Diameter of printing plate | 1.7 mm |

| Diameter of plate mounting tape | 0.38mm |

| simple paste versio machine | One |

| Ceramic anilox roller | 4 pcs, lines from 200-1000 choose by buyer |

| Printing roller | 4 pcs * 3 sets = 12 pcs |

| Unwinding tension controller | LE-30CTA |

| Rewinding tension controller | ZXT-B600 |

| Temperature controller | XMTG-6501 |

| Main Motor | 2.2kw |