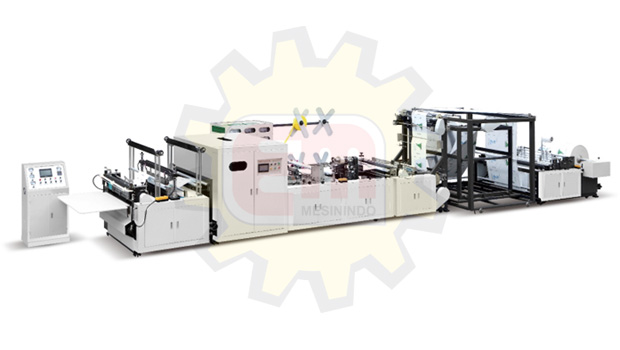

ZHPET 1000/75

ZHPET 1000/75 Sheet Extruder Machine

This Machine is one of the most advanced production lines with matured technology and stability in China. It compared with other same kind equipment can more than over 30% higher in overall efficiency. This line also suitable for PS, PP, PE and PLA sheet production. No need crystallizer and Dryer. Free of crystallization drying system. The new designed line can greatly reduce cost of production.

Note?

- Electric Power Supply:(All Cabinets including main cabinet and control cabinets and all internal cables will be supplied by the seller, buyer’s responsibility is for external cables and cable frame to main panel/input power position of sheet extrusion machine)

- Mains input: 3×380V (Volt)+N+PE

- Current fluctuation max: ?+/-15%

- Frequency: 50HZ Frequency fluctuation max: +/-1.5HZ

- Cooling water supply: used on machinery in closed or open loop circuits must have the general requirement: clean filtered and free of sediments.

- Supply temperature max: 30?

- Supply water pressure: 3-5bar

- Pressure fluctuation: +/-0.5bar

- Return pressure average: 1.5bar

- Water cycle rate: 20-30m3/h

- Compressed air supply: clean, free of oil, dust and water.

- Supply air source pressure: ?6bar

- Pressure variation: +/-1%

- Consumption capacity: 0.9 m3/h

Technical Data:

- Extruder (75/44): Recycle material

- Output: PET: 300-400kg/h

- Product width:1050mm

- Final sheet thickness: 0.2-1.5mm

- Effect width of die: 1200mm

- Effective width of roller: 1200mm

- Roller diameter: 1×Φ350mm 2×Φ500mm

|

Technical Specifications |

|

|

Model |

ZHPET 1000/75 |

|

Power |

380V/3P/50Hz |

|

Water |

10 ?-12?,15m3/h or 20 ?-25?,30m3/h |

|

Air Pressure |

0.6-0.8Mpa |

|

Suitable Material |

PET or recycle |

|

Sheet Specification |

L=950mm, δ=0.20-1.5mm |

|

Max. Capacity |

300-400kg/h |

|

Total Power |

About 230kw |