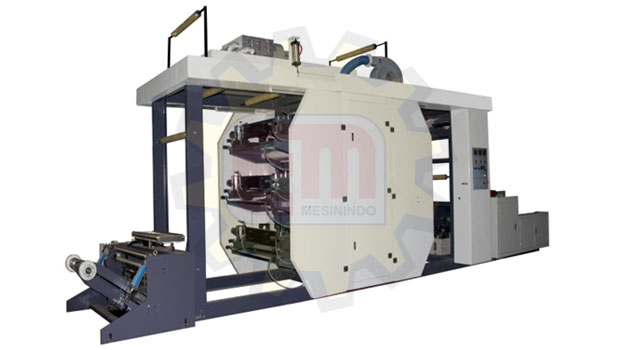

ZYT-1200C6

ZYT-1200C6 Flexo Printing Machine

Main Components of The Machine

Control Unit

- Main motor frequency control

- PLC touch screen control the whole machine

- Reduce motor separate

Unwind Unit

- Hydraulic clamp, hydraulic lift the material, hydraulic control the unwinding material width, it can adjust left and right movement.

- Single workstation

- Magnetic powder brake auto tension control

- Unwind magnetic powder 10kg

- Unwind struggle: Photo-electricity epc

- Unwind shaft: Air shaft (76mm)

- Unwind way: pneumatic automatic feeding

- Traction component: aluminum roller, chrome roller, rubber roller

- Transmission way: Belt

Printing Unit

- Pneumatic lifting and lowing printing plate cylinders auto lifting plate cylinder when the machine is stopped. After that can run ink automatically. When the machine is opening, it will make alarm to start the auto lowering plate printing cylinder.

- Printing component: chrome plated roller, printing cylinder, anilox roller, chamber doctor blade

- Ceramic anilox roller: one piece for each color; Inking with ceramic anilox chambered doctor blade, ink pump circulation

- Printing plate: Resin plate or rubber plate

- Transmission way: Gear + belt

- Method of registration: Manual

- Distance of registration: ± 30°

- Adjustment of printing cylinder up & down: Hydraulic

- Drive method: Variable-frequency motor drive

Heat Drying Unit

- Heating drying method: Adopt with external heating pipe, temperature display, electric current control, centrifugal blower brings the wind

Rewinding Unit

- Back-to-back rewinding

- Pneumatic tension control

- 2.2kw motor vector frequency conversion control

- 3-inch air shaft

- Hydraulic lowering the material

The working principle of the machine (mainly including the following parts):

Unwind unit - Prepress correction - Prepress traction - Printing unit (6color) - Heat drying - Rewind traction - Rewind unit - Control system and console.

|

Technical Specifications |

|

|

Model |

ZYT-1200C6 |

|

Printing Substrate |

Roll paper, plastic film, non - woven fabrics and other flexible packaging materials |

|

Printing Color |

6 color |

|

Max material width |

1200mm |

|

Max effective printing width |

1160mm |

|

Max. Unwinding diameter |

1300mm |

|

Max. Rewinding diameter |

1300mm |

|

Printing length |

230-1000mm |

|

Mechanical speed |

20-130m/min |

|

Printing speed |

5-100m/min (According to the printing of different materials? |

|

Overprint precision |

Horizontal: +/-0.15mm, Longitudinal: +/-0.2mm |

|

Plate thickness (including double-sided adhesive tape) |

2.28mm or 1.7mm (Customers can choose according to their own requirements) |

|

Anilox roller |

Ceramic anilox roller |

|

Ink type |

Water based ink or Solvent ink |

|

Heating power |

24KW |

|

Total power |

36KW |

|

Machine weight |

About: 8500Kg |

|

Machine size |

5600*2600*3250mm |

|

Working power supply |

3PH/380V/50HZ |