13th LEADER-500

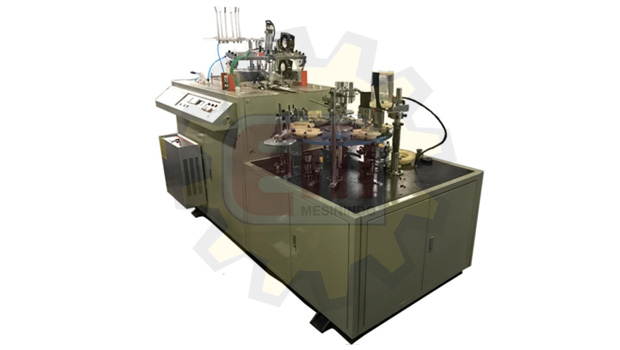

13th LEADER-500 Automatic Non-Woven Box Bag Making Machine with Online Handle Attach

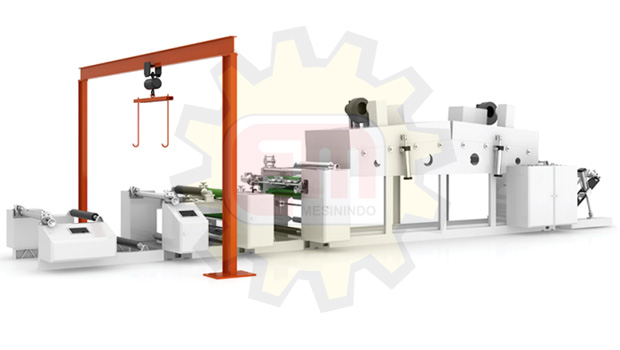

Process flow

Auto non-woven roll feeding-> Auto tension control, centralization-> Mouth folding-> Handle welding->

Handle folding-> Online impression-> Bag forming-> Bag folding -> Bag collection

Patent

- Leader is newly researched and developed in 2013, patent No.: 201310336180.6

- Leader is concentrated in non-woven box bag manufacturing, use non-woven fabric and non-woven laminated fabric as raw material.

PP non-woven lamination material requirement

PP non-woven (pp melt index 16, the calendar temperature 170-180)

Lamination material

PP:PE =4:1 Opp thickness should be 0.015mm-0.018mm

PP melt thickness 10-15gsm

Opp should be shining opp, both side with corona

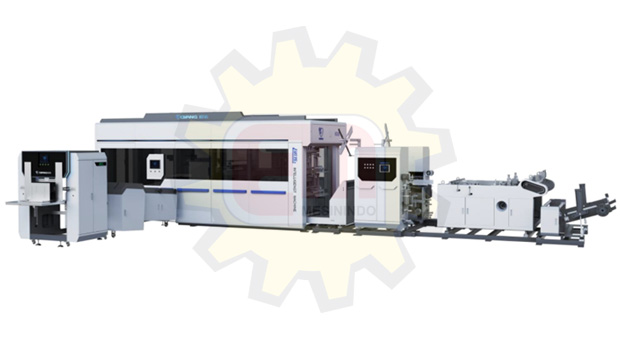

1-2-1, Leader can perform good with few labour, higher efficient & lower cost, it’s the most competitive

machine in non-woven bag making.

1-2-2, non-woven bag has more advantages when compare with nonwoven sewing bag and paper bag.

|

Technical Specifications |

|

|

Model |

13th LEADER-500 |

|

Roller width |

50-1160mm |

|

Bag making speed |

60-80pcs/min |

|

Bag width |

180-500mm |

|

Bag height |

180-450mm |

|

Gusset |

80-200mm |

|

Power supply |

380V |

|

Total power |

35KW |

|

Rated power |

12KW |

|

Overall size |

L 9500 x W 6300 x H 2600 mm |

|

Weight of machine |

12000kgs (40HQ*1) |

|

Handle length |

380-570mm |

|

Handle width |

25mm & 30mm |