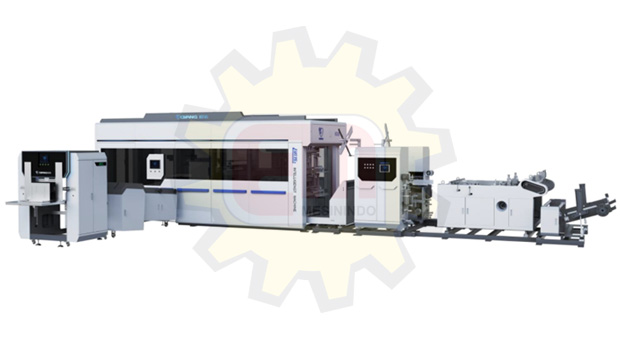

GW-1050WLM

GW-1050WLM Cigarette paper and foil Laminating Machine

1. The machine has auto tension control.

2. Two unwind adopt magnetic powder brake with automatic tension control.

3. Laminating pressure part adopts ordinary iron roller combined with Rubber roller. It is extrusion laminating method

4. It adopts Shaft-less installation of Anilox roller for coating and Printing cylinder

5. Mechanical transmission using shaft drive, reliable and stable in operation;

6. Oven pneumatic opening method.

7. Hot air circulation heating oven, which improve the heat utilization rate and increase the speed of equipment operation;

8. The winding part use automatic hydraulic lift =. It can make the winding diameter to φ1200mm.

|

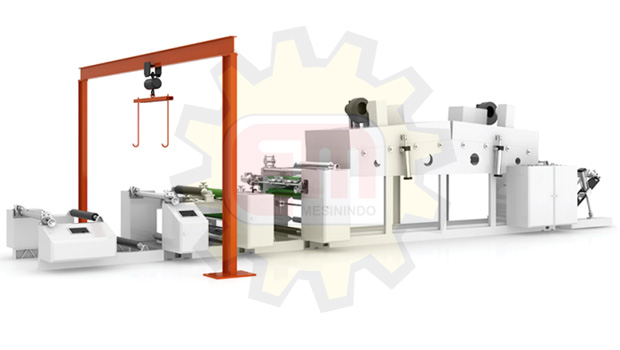

Technical Specifications |

|

|

Model |

GW-1050WLM |

|

Width of the material roller |

10-1000mm |

|

Thickness of the material |

Foil and Paper |

|

Machine speed |

10-90m/min |

|

Max Diameter of the Two Unwind |

Paper: ø1000mm Foil: ø600mm |

|

Max Diameter of the Rewind |

Ø1200mm |

|

Main motor: Siemens inverter motor |

11kw |

|

Rewind Siemens inverter Motor |

11kw |

|

Heating system Power |

45KW |

|

Machine Power |

70KW |

|

Overall Dimension |

10500mm*3000mm*1900mm |

|

Weight |

5500kg |