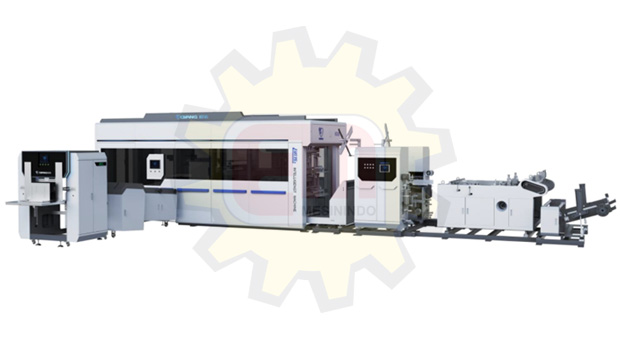

BZK-1400/4

BZK-1400/4 Semi-automatic Four-Color Printing Machine

Printing part functions:

• This machine is common printing machine of chain feeding.

• Adopt heavy rail to ensure the equipment’s stability of working and separating.

• Pneumatic diaphragm pump gives the ink, you can adjust the flow of the ink at will to improve ink evenness (not including air pump)

• Adopts 360 degrees computer numerical control rapid phase adjustment, reading dial set, with an automatic counting device.

• The rocker panel design and all the gears transmission to reduce the errors of color-matching. When adjust the axis space, the meshing gap remains the same.

• The paper-feeding way was designed to cross slipper to strengthen the accuracy.

• The gears are steel parts quenched, ensure service life.

• Ink roller part can rise pneumatically and run alone, in case printing ink dries up when the machine stops.

• Use spray pump group oil supplying to improve equipment lubrication.

Features:

• The thickness of the solid core wallboard is 40mm; the key parts are all made by high-precision machining center.

• All driving shaft and roller are high quality steel, high-precision dynamic balance correction, hard chromium plating and surface grinding.

• Main shaft locking using high rigidity of locking, have higher accuracy than the traditional key locking, convenient to dismounted.

• All the gear transmission, steel parts quenching inclined gear transmission, is used for a long time, high precision adjustment.

• The transmission part adopts satellite swing type, eliminating connection clearance, suitable for long time high-speed printing. Matching color precision is higher for 3-layer, 5-layer and 7-layer.

|

Technical Specifications |

|

|

Model |

BZK-1400/4 |

|

Max mechanical speed (piece/min) |

80 |

|

Economic speed (piece/min) |

50-60 |

|

Max printing area |

2500x1450mm |

|

Max paperboard size |

2700x1450mm |

|

Thickness of standard printing plate |

3-8mm (can adjust) |