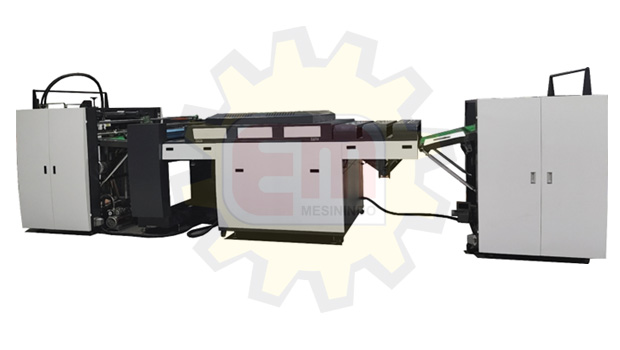

BPC-1000NS

BPC-1000NS Inspection Machine

Features:

High speed line scan camera:

Adopt imported color camera. The camera has the advantages of fast acquisition speed, good imaging effect, small size and wide range of application.

Specific Lens

The imaging lens of the detection system adopt industrial lens. Compared with other brands, the lens has better clarity, distortion control, and better color and image restoration.

Led specific light source

In order to ensure the image acquisition quality of most materials, the special LED light source is used in our machine. The light source adopts cavity reflection design. Through the diffuse reflection in the tunnel cavity, the brightness of the light outlet is uniform, so it can eliminate the interference of laser, gilding and product surface reflection, obtain stable and high-quality product image. It has the incomparable advantages of general strip light source.

Special software system for label quality inspection

BPC company has a professional R & D team with 10 years of continuous research and development. In view of the different testing needs of various printing industries, we have developed a number of testing software with independent intellectual property rights to meet the needs of different industries. At the same time, we have carried out special research and development in terms of operation convenience and parameter adjustment efficiency. For new products, items can be tested after 1 minute’s Initial setting.

The detection software adopts the distributed computer architecture to support the expansibility of the system. According to the different quality standards, different detection accuracy can be set in different areas to realize the partition detection. It can meet the basic detection requirements of the label industry.

The software interface is simple and practical, and in order to improve the stability of the equipment, BPC adopts high-end electrical components. The electrical control module consists of industrial computer system, signal transmission, control unit, image acquisition unit and power distribution unit.

|

Technical Specifications |

|

|

Model |

BPC-1000NS |

|

Supply Voltage |

Single-phase 220V 50/60HZ |

|

Power |

5KW |

|

Max Width for entering paper |

320mm |

|

Max detection size |

320*300mm |

|

Minimum detection size |

50*30mm |

|

Resolution |

0.09mm |

|

Detection Speed |

80 meters per minute (depend on label size and print content) |

|

Defect Detection |

illegible print, missing print, dirty spot, overprint error, color deviation etc. |

|

Barcode Detection |

One-dimensional code, EN8, EN13, EN39, EN128 (The distance between lines should be more than 1.5mm, and the bar code should be clear) No variable code Minimum color difference detection (?E) ? E ≥ 3 |

|

Visual detection software system |

Visual detection software made in Taiwan Skyeye (Version V5.0) Software detection module for general defect Detection module for color difference Size detection module Barcode detection module |

|

Paper receiving method |

Servo drive system, magnetic powder tension control Manual receiving paper roll fixation |

|

Unsuitable detection items |

(1) Paper with excessive glue(white), varnish defects, bubbles, pockmarks. The transparent label on the transparent backing paper should be checked for die cutting and slightly wrinkled (Other companies also need to use 2 sets of cameras to achieve the above functions). (2) Partial laser film, small characters (It's not clear from the camera). |

|

Dimension |

1580 x 1200 x 1480mm |