BY-750

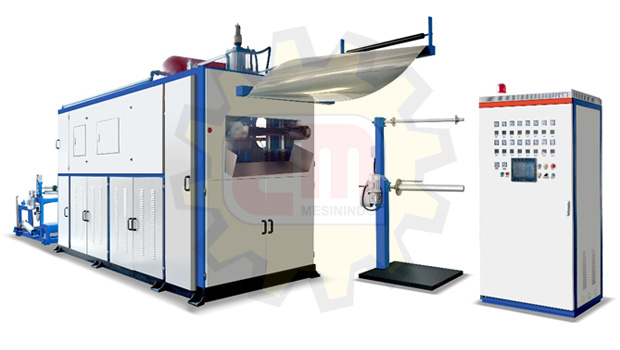

BY-750 Hydraulic Cup Thermoforming Machine

BY-750 Hydraulic Cup Thermoforming Machine

Main Machine Part:

- The frame is welded with standard 100×100, 100×50, 10# and steel plates. The whole steel plate is laid on the bottom of the machine to improve the stability of the whole machine.

- Mold movement (Closed / Open) adopts Hydraulic system to control, 4 pillars. It adopts TAIWAN YUKEN BRAND.

- Oil pump motor adopts 11kw WNM BRAND MOTOR. It is best quality and save energy.

- Main Pneumatic components use Japan SMC original solenoid valve, it is more stable.

- Feeding Sheet device adopts 3.7 kw to control.

- Plug device adopts Air cylinder, (can be customized use Japan servo motor)

- The lubrication system adopts automatic lubrication device, positive displacement oil, stable and efficient, and can be monitored in real time.

- The chain adopts combined structure, with cooling device, the width can be automatic adjust.

- Heating system: Adopts Jiangsu brand infrared heater 800W.Stainless up Down heating. Upper 8×12, Down 8×11.Heating oven can go in/ out.

- Air source filter adopts triad air source filter air flow size adjustable

- 4 guide pillar Φ 80 mm. It is made of 45 # steel after tempering after fine grinding hard chromium plating surface.

Leftover material rewinder

- Automatic rewinder device 1 set

Auto loader

- Reduction drive?0.55 KW motor 1 Set

- Pneumatic pressure: Air cylinder SC50 X 25 2 Sets

- Pneumatic feeder: Air cylinder SU80 X 400 2 Sets

Electrical control cabinet

- Whole control system 1 set

- PLC: SIEMENS, GERMANY, TOUCH SCREEN: WEINVIEW,10.4 CUN, TAIWAN

- Temperature controller: Good brand Regulating module:

- Proximity switch: Schneider, France. Intermediate relay, Contactor, Button Switch adopts CHINT

- Ammeter, Voltage, K thermocouple adopt famous domestic brands

|

Technical Specifications |

|

|

Name |

Parameter |

|

Suitable material |

PP PS PET HIPS |

|

Forming area |

750×420mm |

|

Machine travel |

220mm |

|

Production speed |

15-30 cycle/min |

|

Total power |

≤60kw |

|

Weight |

6.5T |

|

Dimension (LxWxH) |

4200×1600×2500mm |