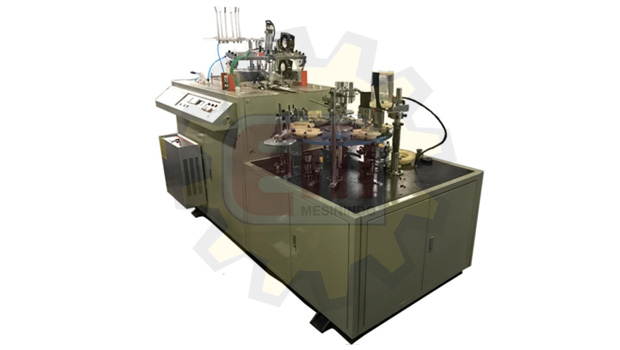

F-1000

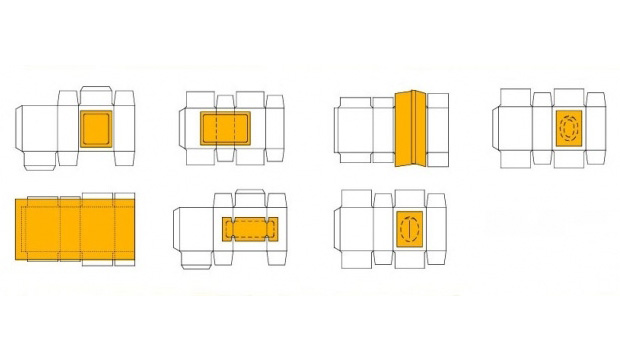

F-1000 Window Patching Machine

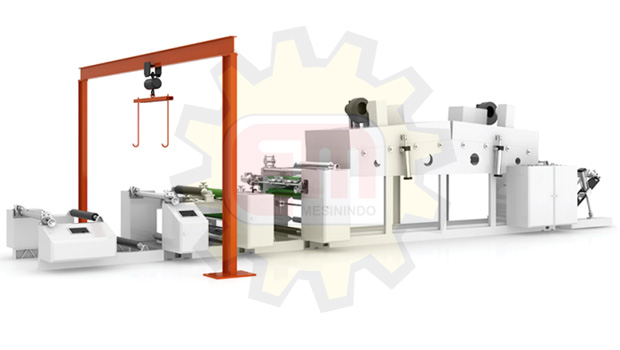

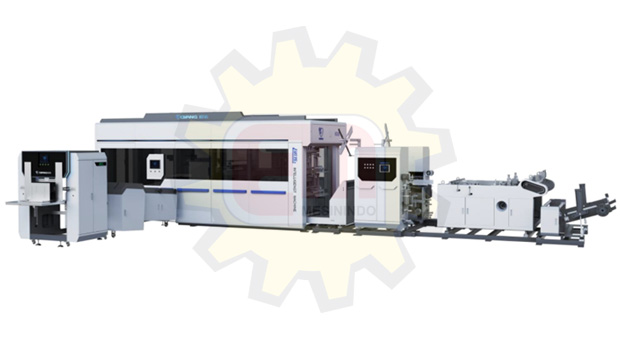

This Machine is used to film the windows of various paper boxes. It is developed on the original window patching machine in light of customer’s requirements. Our research and development team, through the continuous improved & perfect human design, let the machines be easier to operate and better in efficiency, accuracy and stability. Both basic components and major automated accessories employ the proprietary technology of this company.

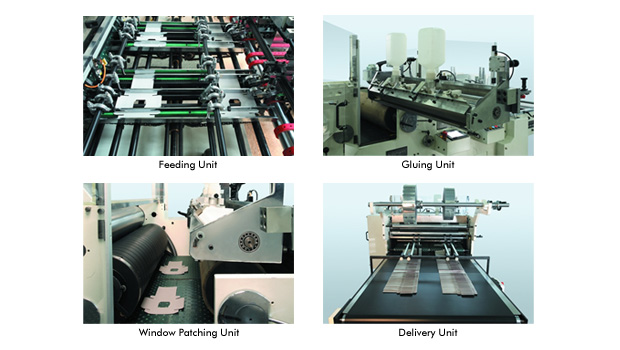

• Equipped with Kohmann professional bottom belt feeding system and two different types of lifting system which is operated with piling table lifting system and belt lifting system. The feature of the piling table is the belt can run continuously. Boxes move to piling table by moving up & down. The flexible piling table can feed different boxes and also avoid scratches. Production can be increased by high speed belt lifting system

• The feeding system designed by Kohmann is the most updated feeding technique. Timing belt feeder equips with automatic air suction system. There are four drive chains in chain adjustment

• The unique feeding gate in feeding unit can be adjusted without any tool

• Upper rail is made up of 5mm flat steel and connected with the lifting part in middle of chase which ensures the correct positioning of rail, cardboard and chain due to the well-set structure. The accurate setting remains even thought the sheet is jammed and can be micro-adjusted

• Gluing unit consists of the chromeplated gluing roller, glue separating board, side limit and gluing pattern roller

• Gluing unit can be easily pulled out which is easy to set up and clean

• Adjustable glue separating board controls the range and amount of glue

• Cylinder lifts the gluing roller and will be controlled by another independent motor when machine stops to avoid from the glue leakage

• The gluing pre-make ready table is available to prepare the gluing pattern outside the machine which is convenient

• The boxes are fed to window sticking unit from gluing unit by the air suction table which is running individually and helps sensor checking. If there is no sheet, air suction table goes down immediately to avoid from the glue

• Special material made air suction cylinder increase the speed and prevent the plastic film from scratching

• Knife roller rotates and crosses with the fixed knife bar. Plastic film is cut more flat.

The unique knife roller and the adjustable air blasting / suction system help to stick the plastic film on the window more smoothly

• The height of wider delivery belt can be adjusted and make the sheet pile more tidy

• The speed of belt can be adjusted to be synchronous with the machine speed

|

Technical Specifications |

|

|

Model |

F-1000 |

|

Max. blank size (WxL) |

1000x710 mm (1-Stream); 485x710 mm (2-Stream) |

|

Min. blank size (WxL) |

80x100 mm |

|

Max. window size (WxL) |

840x500 mm (1-Stream); 405x500 mm (2-Stream) |

|

Min. window size (WxL) |

30x45 mm |

|

Cardboard thickness |

Cardboard 200 gr/m2 ~ 2.000 gr/m2; Corrugated board Max. 6.0 mm |

|

Film thickness |

0.03 ~ 0.2 |

|

Film material |

PET, PVC, PP, PE and paper. Other special effect film such as shining film, matt film, glittery film, colored film, printed film, UV filtering film and fluorescent film, etc. |

|

Sticking accuracy |

Left & right ± 0.5 mm; up & down ± 1 mm |

|

Max. speed |

Up to 36,000 cartons/hour depending on product size 150pcs/min/lane (blank length over 330 mm); 300pcs/min/lane (blank length below 330 mm) |

|

Dimension (LxWxH) |

4225x1700x1500 mm |

|

Weight |

3300 kg |

|

Main motor power |

3 kw |

|

Glue roller motor power |

0.09 kw |

|

Delivery motor power |

0.37 kw |