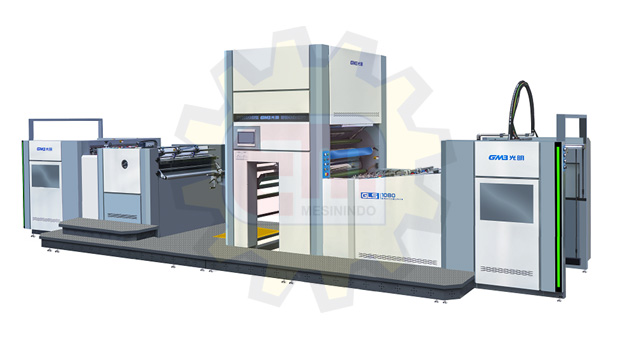

GLS-1080

GLS-1080 Water-base Automatic Laminating Machine

GLS-1080 Water-base Automatic Laminating Machine

Standard Equipment’s:

Feeder

- Sheets pre-stacker provides continuous feed without a stop

- Servo-controlled feeder head, synchronizing with the host speed, replenishes sheets

- Sheets gap sensor for self-protection

- Overlap regulator adjusts the sheets overlapped length

- Side-lay regulator aligns sheets

Laminator

- Electromagnetic-heated, chrome laminating roller and hydraulic-pump driven rubber roller

- High-precision glue applying roller and glue scraper

- Large diameter steel roller(Φ800) and strong hot wind drying system dry glue instantaneously

- Pre-coated film mounted on a quick-change, micro-adjustable airshaft

- Airshaft ensures precise film release tension and speed

- Film rolls slitting and perforating mechanisms

- Film rewinders for the left film that is cut

Sheeter

- Anti-curl assembly de-curls thin sheets after thermal lamination

- Steer wheels exert negative force on one side to help with sheeting

- Rotatory knife+pneumatic sheeter

Stacker

- Corrugated delivery system flattens and delivers sheets

- Side joggers and back-stop stack sheets in order

- Non-stop automatic stacker with a sheets counter

Others

- Suitable for both pre-coated film lamination and uncoated film lamination

- Feed, overlap and side-lay adjustment, powder removal, laminating, drying, sheeting and stacking are finished in one pass

|

Technical Specifications |

|

|

Model |

GLS-1080 |

|

Max Paper Size |

1080×900mm |

|

Min Paper Size |

300×260mm |

|

Laminating Speed |

0-100m/min |

|

Paper Thickness |

100-500g/m² |

|

Gross Power |

90/46kw |

|

Weight |

8900kgs |

|

Overall Dimensions |

9650×2350×3000mm |