Hopper Receivers

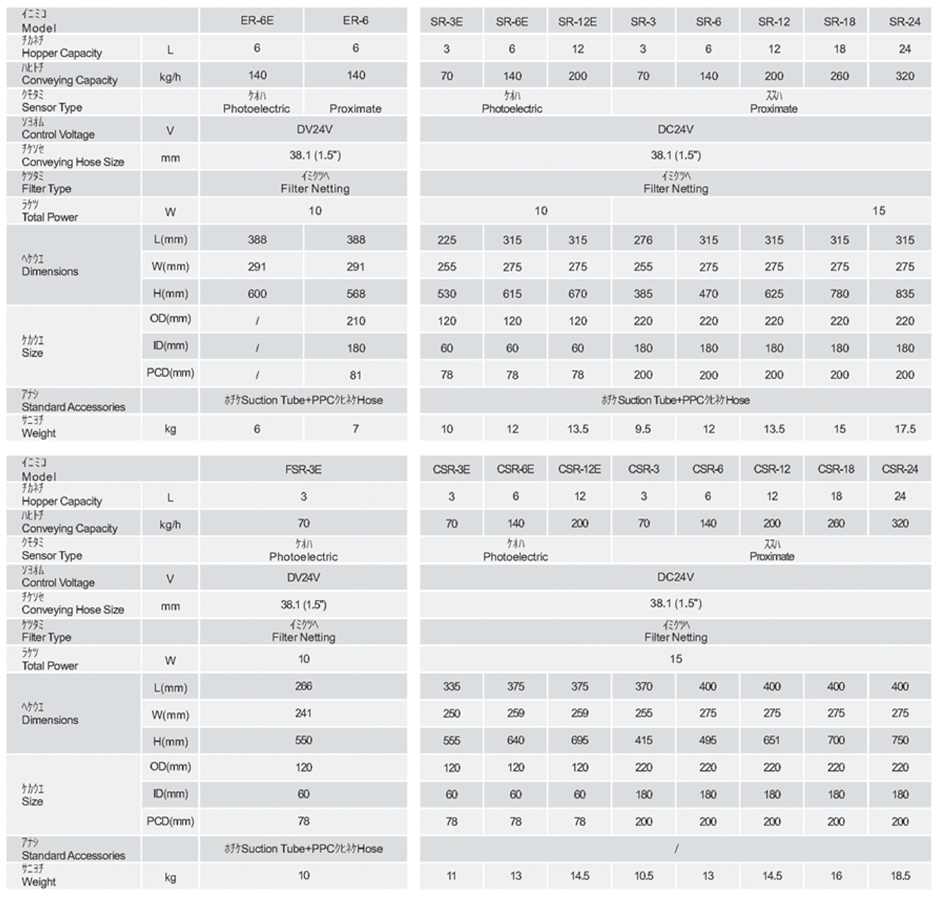

ER / SR / FSR / CSR Hopper Receivers

Hopper Receivers are fitted with sensors to control materials suction smoothly. Diverse Hopper Receivers-standard type, stainless type and for optics type are provided according to customers' various requirements. Stainless hopper receivers ensure no contamination to raw materials and they are equipped with see-through window to monitor materials levels which are especially suitable for application of optics. They can be mounted onto plastic injection molding machines directly or to work with separated autoloaders and give more convenient on cleaning or changing materials.

- Stainless steel construction used by ER/FSR series for ensuring material free and for all structural by SR/CSR series from contamination that working with detachable autoloaders;

- Mechanical stainless flap fitting on ER/SR/CSR series that need not to be adjusted according to different material;

- With hopper receivers and bases are locked by hinge, FSR/SR/CSR series is easy for dismantle;

- A diaphragm valve fitting on CSR series if several central hopper receivers want to share same blower for centralized feeding system;

- FSR series is particularly designed for optic product use for reducing powder to cause any defects for enhancing productivity qualities.

- Autoloaders equip with photo sensors which are mounted onto the feeding port of injection molding machines; autoloaders equip with proximity switch which are mounted onto the hopper dryers.

- To adopt glass tube with photo sensor ( static capacity detection) for precisely detect material conveying.

- To be fitted with stainless screener for easy filtering dust.