ISBM Series

ISBM Series Single Stage Injection Stretch Blow Molding Machine

1. The whole process including mould injection, stretch blowing and off-molding can be finished within one step, which means more energy efficiency and high quality for product. The injection blowing molding products are thinner and better uniformity than old style ones, which can save 50% materials. Meanwhile, hygienic requirement is guaranteed.

2. Compact structure cover small floor coverage, which can save more cost than traditional machines.

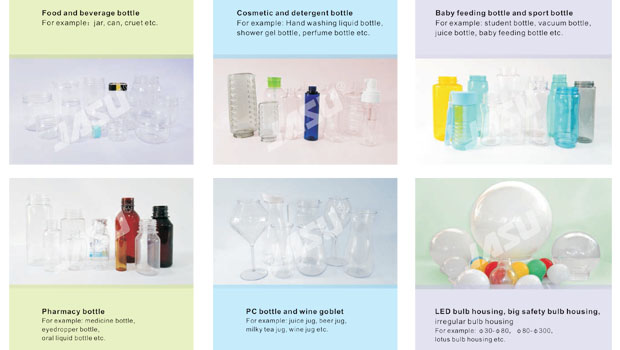

3. Widely used for manufacturing bottles for pharmaceutical, healthcare, food, beverages, cosmetics, lampshade and other applications.

4. Can use recycling material with the lowest cost.

|

Injection part |

Item |

Unit |

IB1100-2 |

ISB 800N-3 |

ISB 800AN-3 |

ISB 1100N-3 |

ISB 1100AN-3 |

ISB 1100AN-80T-3 |

ISB 950N-4 |

ISB 950AN-4 |

|

|

Screw Diameter |

mm |

50 |

40 |

50 |

40 |

50 |

50 |

40 |

50 |

||

|

Screw L/D Ratio |

L/D |

20.5:1 |

20.5:1 |

24:1 |

20.5:1 |

24:1 |

24:1 |

20.5:1 |

24:1 |

||

|

Screw Speed |

r/min |

0-150 |

0-190 |

0-150 |

0-190 |

0-150 |

0-150 |

0-190 |

0-150 |

||

|

Theoretical injection capacity |

cm³ |

481 |

238 |

481 |

238 |

481 |

481 |

238 |

481 |

||

|

Injection Pressure |

Mpa |

176 |

174 |

176 |

174 |

176 |

176 |

174 |

176 |

||

|

Max. hydraulic Pressure |

Kg/cm |

140 |

140 |

140 |

140 |

140 |

140 |

140 |

140 |

||

|

The actual injection quantity |

g(ps) |

452 |

225 |

452 |

225 |

452 |

452 |

225 |

452 |

||

|

Oz |

16 |

8 |

16 |

8 |

16 |

16 |

8 |

16 |

|||

|

Screw Stroke |

mm |

245 |

190 |

245 |

190 |

245 |

245 |

190 |

245 |

||

|

Clamping part |

Blow Clamping Force |

Kn |

80 |

80 |

80 |

150 |

150 |

150 |

80 |

80 |

|

|

Clamp Tonnage |

Kn |

600 |

400 |

400 |

600 |

600 |

800 |

400 |

400 |

||

|

Wheel Diameter |

mm |

1100 |

800 |

800 |

1100 |

1100 |

1100 |

950 |

950 |

||

|

Max. Height |

PP PET PETG Tritan PS PC |

mm |

|

200 |

200 |

200 |

200 |

200 |

200 |

200 |

|

|

PC PETG Tritan PS |

140 |

220 |

220 |

220 |

220 |

220 |

220 |

220 |

|||

|

Open vertical mode trip |

mm |

430 |

570 |

570 |

570 |

570 |

600 |

600 |

600 |

||

|

Others |

Max. Pump Pressure |

Mpa |

16 |

16 |

16 |

16 |

16 |

16 |

16 |

16 |

|

|

Servo Motor |

Kw |

22 |

22 |

22 |

22 |

22 |

22 |

22 |

22 |

||

|

Mode opening & mode locking use ordinary motor (double pump) |

Kw |

|

22 |

22 |

22 |

22 |

22 |

22 |

22 |

||

|

Electric power |

Kw |

12.2 |

8.9 |

12.2 |

8.9 |

12.2 |

12.2 |

8.9 |

12.2 |

||

|

Tank volume |

L |

400 |

420 |

420 |

420 |

420 |

420 |

420 |

420 |

||

|

Dimension (LxWxH) |

M |

4.5x1.7x3.3 |

4.2x1.75x3.4 |

4.2x1.75x3.4 |

4.5x1.95x3.4 |

4.5x1.95x3.4 |

4.5x1.95x3.4 |

4.2x1.75x3.55 |

4.5x1.75x3.55 |

||

|

Machine Weight |

Ton |

8 |

5.5 |

6 |

8.5 |

9 |

9.5 |

6.5 |

7 |

||