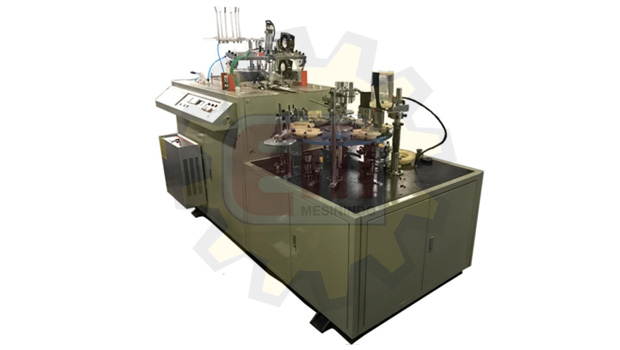

JZ-20031

Double Wire Forming Machine

The JZ-20031 twin loop wire forming machine produces double wires if a wide range of a wide range if diameters and different pitches, using nylon-coated wire from spills, the wire is unwound from a spool, straightened and smoothed by the special rectifying tools of the machine and then is guided via guide rollers into the forming unit where the wire is formed into zigzag carpet and further to C shape profile the double wire loops formed. The endless double wire connecting from the forming machine, via the connecting table to the spooling machine. The connecting table is to “sense” the length of the formed double wire loops and to control the spooling machine when and how fast to wind.

| Technical Spesification | |

|---|---|

| Model | JZ-20031 |

| Speed if service | 350-500 |

| Power Source | 220V/50Hz |

| Main motor power | 0.75Kw/h |

| Main dimension | 2700x750x1510 mm |

| Net weight | 350 Kg |