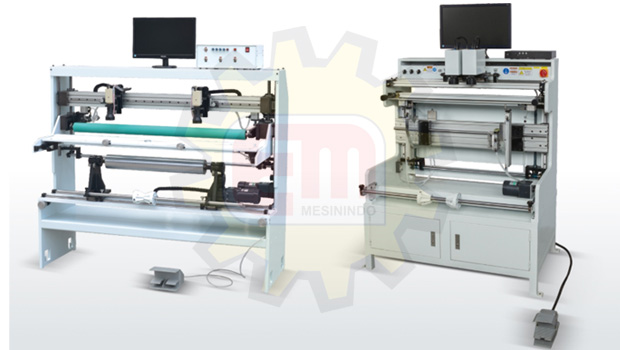

RDC-2512

RDC-2512 Rotary Die Cutting Machine

Function and characteristic:

- High pressure centrifugal fan can control the wind pressure with frequency conversion according to the degree of warping of cardboard to ensure high speed and accurate transmission of warped cardboard and thin cardboard.

- Separate paper feeding device, according to the need to choose paper. To ensure that large scale cardboard can also be processed.

- Install 7-inch touch screen, which can automatically display the production quantity and production speed. Can design production quantity.

Die Cutting Unit

Die rubber roller

- Die rubber ?388.9mm, centrifugal cast alloy steel pipe, grinding processing, hard chrome plating, static balance.

- Die rubber pad selection "Germany Dipai", width 250mm, normal can be used 8 million times, mechanical left and right movement 30mm, and equipped with radial differential device, so that the rubber pad wear average distribution, greatly improve the service life of the rubber pad.

- Die cots are equipped with built-in differential automatic compensation device, so that the rubber pad and the template roll automatically maintain the same linear speed. Make the product size of each batch consistent, thereby reducing production cost.

- The machine is equipped with die rubber adhesive correction device, which can be used after repeated correction.6) The grooving part is equipped with interlocking control switch to realize emergency stop, urgent delivery or return to feed paper.

Template roller

- Template roller ?360mm, centrifugal cast alloy steel pipe, grinding, hard chrome plating, static balance.

- The template is fixed with screw hole M10, the axial spacing is 100mm, and the radial spacing is 18 equals (the Angle between holes is 20 °).

- The thickness of the cutting die board: 16mm (three layers of cardboard) 13mm (five layers of cardboard).

- The template roller is equipped with a transverse adjustment device for stretching 10mm from left to right. The PLC control mode is adopted for digital display, and the adjustment precision value is 0.1mm.

- The template roller and die rubber cots are automatically removed by cylinder eccentricity device under the condition of no die cutting, which can reduce the no-load of the machine and prolong the life of die rubber and cutter die.

|

Technical Specifications |

|

|

Model |

RDC-2512 |

|

Max. feeding size |

2500x1200mm |

|

Max. die cutting size |

2400x1100mm |

|

Min. feeding size |

750x360mm |

|

Paper feeding mode |

Auto feed |

|

Paper feeding speed |

120 pages/min |

|

Arrange mode |

Manual |

|

Main motor |

11kw |

|

Repair motor |

0.75kw |

|

Phase motor |

0.37kw |

|

Baffle motor |

0.37kw |

|

Bellows motor |

7.5kw |

|

Dimension |

3.7x1.7x2 m |