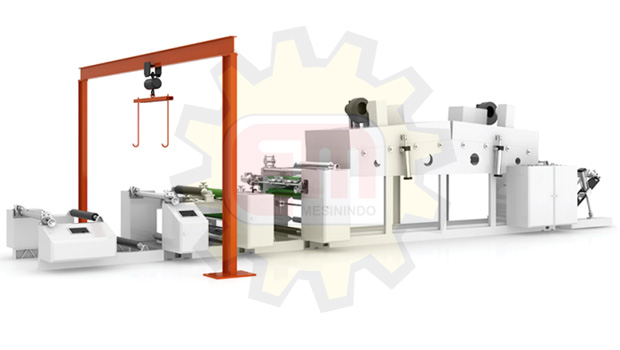

SJFM 1100-1800A

SJFM 1100-1800A High Speed Extrusion Coating Machine

Features:

1. PLC man-machine interface centralized control, machine, electricity, gas, integrated design.

2. Highly efficient corona device

3. Easy and quick filter screen exchange

4. Double station unwinding and rewinding, automatic nonstop roll exchange

Form of production:

Single-layer lamination / three-layer compounding/ multilayer compounding (one-time seven layers available, increase the extrusion unit)

|

Technical Specifications |

||||

|

Model |

SJFM-1100 |

SJFM-1300 |

SJFM-1600 |

SJFM-1800 |

|

Width of die |

1200mm |

1400mm |

1800mm |

2000mm |

|

Width of finished product |

500-1000mm |

600-1250mm |

800-1500mm |

900-1700mm |

|

Max. speed |

100-150m/min |

100-150m/min |

100-150m/min |

100-150m/min |

|

Coating thickness |

0.01-0.1mm |

0.01-0.1mm |

0.01-0.1mm |

0.01-0.1mm |

|

L/D ratio for screw |

Φ95mm×30 |

Φ105mm×30 |

Φ120mm×32 |

Φ140mm×32 |

|

Diameter for roll unwinding and rewinding |

Φ1300mm |

Φ1300mm |

Φ1300mm |

Φ1300mm |

|

Overall size L*W*H(MM) |

9600×8300×3200 |

9600×8600×3200 |

9600×9000×3200 |

9600×9300×3200 |

|

Power |

70kw |

80kw |

100kw |

130kw |

|

Compounding roller |

Φ510mm |

Φ510mm |

Φ510mm |

Φ610mm |

|

Applicable for base material |

Paper / non-woven / PP woven sack, etc |

|||

|

Extrusion resin |

LDPE, LLDPE, PP, EVA, EAA, etc |

|||