WSFM-1300C

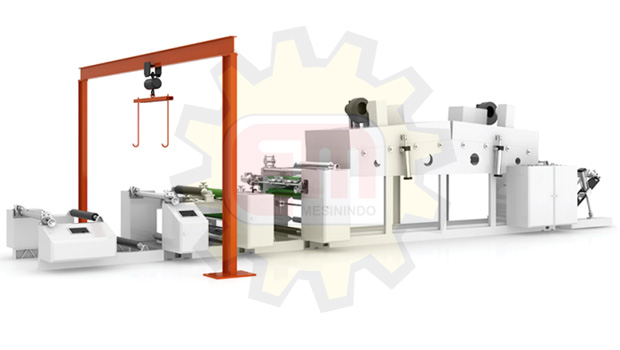

WSFM-1300C Film Extrusion Laminating Machine

The principle of the process is that the plastic resin (PE) is plasticized by the screw and then extruded from the t-die. After being stretched, they are attached to the surface of the paper. After cooling and compounding, the paper has the functions of waterproof, oil proof, anti-seepage, heat sealing, etc. The whole machine consists of feeding device, extruder, T-die, unwinding part, compounding part, winding part, correcting device, corona, trimming device, Cooling system, electrical measurement and control system and other components.

The whole production process does not use any chemical solvents, it is environmental protection and pollution-free, and the finished products are widely used in food packaging, such as disposable paper cups, cold drink cups, burger paper bags, paper lunch boxes, food paper bags, aviation cleaning bags and so on.

Technological process:

Paper Unwinder (Auto splicer) à web guiding à Corona treater à Extrusion and compounding part à

Corona à Edge Trimming à Rewinding

|

Technical Specifications |

|

|

Model |

WSFM-1300C |

|

Suit laminating resin |

LDPE, PP, etc. |

|

Suit base material |

Paper (60—400 g/m²) |

|

Max mechanical speed |

300m/min |

|

Maximum working speed |

250m/min depend on coating gram |

|

Coating width |

500-1200; guide roller width 1300mm |

|

Coating thickness |

0.008-0.05mm (Single screw) |

|

Coating thickness error |

≤±5% |

|

Auto tension setting range |

3-70kg full margin |

|

Max extruder quantity |

220 kg/h |

|

Compound cooling roller |

∅ 800×1300 |

|

Screw Diameter |

∅ 110mm ratio 35:1 |

|

Max unwind diameter |

∅ 1600mm |

|

Max rewind diameter |

∅ 1600mm |

|

Unwind paper core diameter |

3” 6” |

|

Rewind paper core diameter |

3″ |

|

Extruder is drove by |

37kw |

|

Total power |

about 250Kw |

|

Machine weight |

about 32000kg |

|

Outside dimension |

17100 mm×10500 mm ×4000 mm |

|

Machine body color |

White |