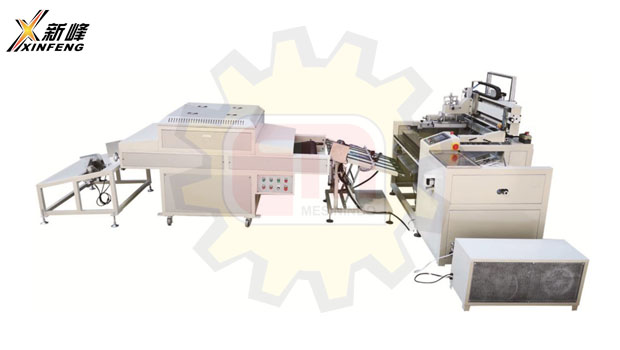

XF-6090A

XF-6090A Automatic Screen Printing Machine

The new optimized semi-automatic screen-printing machine realizes automatic feeding, automatic alignment, automatic printing and automatic feeding. The Chinese/English interface is simple and easy to learn, which not only reduces the labor intensity and the technical requirements of operators, but also improves the printing stability by replacing manual work with machine positioning. The advantages of saving labor and the flexibility of small batches of semi-automatic equipment are also provided. Semi-automatic screen-printing plate is used to reduce the cost of updating.

Fully automatic screen-printing machine is controlled by PLC and touch screen. It is easy to operate and learn. It can be matched with tunnel dryer, UV photosetting machine and paper clip dryer. It is suitable for transfer paper, film switch, packaging, label and other industries.

|

Technical Specifications |

|

|

Model |

XF-6090A |

|

Max. printing size |

600x900mm |

|

Accuracy |

< 0.05mm |

|

Platform size |

700x820mm |

|

Max. frame size |

950x1300mm |

|

Material thickness |

0-1mm |

|

Speed |

50-1000pcs/h |

|

Printing Squeegee corner |

0-30° |

|

Frame operating |

± 5mm |

|

Power |

3N 50Hz 380V 5.0Kw |

|

Air supply |

0.4-0.6 MPS |

|

Overall dimension |

2850x145x1600mm |

|

Weight |

800kg |