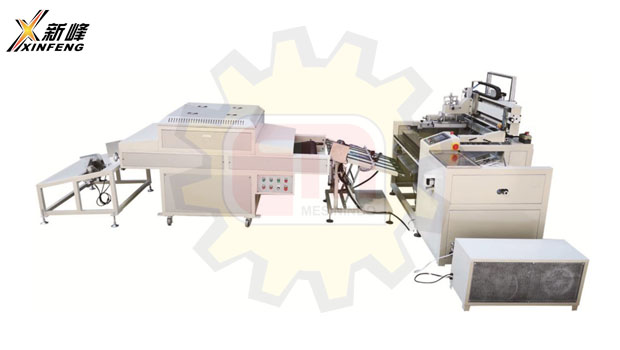

XF-720

XF-720 Automatic Stop Rotary Drum Printing Machine

Feature:

- FEEDER: Efficient and stable compact feeder head design, with two suck two delivery four suction. Adjust and delivery different thickness paper stable.

- FEED BOARD: Feed surface is worked by plating, avoid the rear of printing substrates to be scratched, at the same time feeding is very smooth; with the sensitive sensor it will stop automatically if without paper.

- CYLINDER AND REGISTERM SYSTEM: the vacuum cylinder surface is stainless steel canister after fine polish; firm feed teeth is suitable for any thickness material and can be changed or adjusted easily; side lay is controlled by up and down bearing which get high accurate precision for special material like thin paper and film etc; The pull-push side lay with top and bottom bearing make the overprint with high precision for both thin and thick paper.

- SQUEEGEE BLADE AND INK RECLAIMING BLADE: the up and down of squeegee blade and ink reclaiming blade is controlled by cam which ensures printing pressure equally, however spot point or parts, all can be printed accurately; the pressure of blade can be adjusted at any moment; squeegee with the printing graphics if more clearly and the ink layer is more well-proportioned. The squeegee with pneumatically pressure kept device which make the printing image more clear and ink layer more equal.

- SCREEN CARRIAGE DRIVE RAIL: Adopts linear lead rail and bead bearing, avoid quake and buzz when high speed working, ensures printing stably and smoothly.

DELIVERY BOARD: Delivery board can be turned down by 90 degree. easy to adjust the screen frame, fix blade, clean and inspect; with vacuum adsorption ensures delivery smoothly. The thick paper anti-rebound device ensure the thickness is delivery smoothly.

|

Technical Specifications |

|

|

Model |

XF-720 |

|

Max. sheet size(mm) |

750x540 |

|

Min. sheet size(mm) |

350x270 |

|

Max. printing size(mm) |

720x500 |

|

Frame size (mm) |

880x880 |

|

Thickness (gsm) |

80-400 |

|

Printing speed (p/h) |

1000-3600 |

|

Total power(kw) |

8.3 |

|

Weight (kg) |

3800 |

|

Dimension (LxWxH) |

4200x1800x1450 |