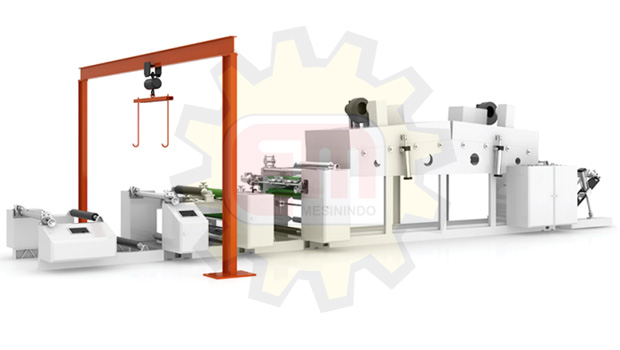

CZL-1000

CZL-1000 Automatic Slotting Machine

Main Structure and Function Characteristics

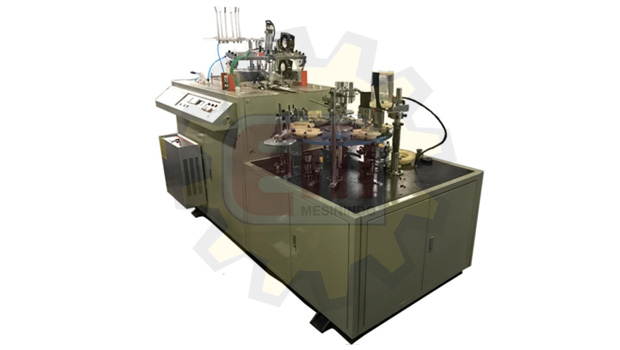

- Paper feeding roller adopts patterned roller, feeding roller pressure adopts eccentric wheel adjustment with left and right eccentric wheels, can adjust the pressure synchronously.

- Leading edge feeding department adopts vacuum adsorption device, make the feeding more smoothly, to avoid the slotting error to make upper paperboard misplace when feed paperboard, can fit to each kind of paperboard with different quality, and sending paper stable and accurate.

- Slotting knife discs adopt full steel processed, slotting knives adopt sawtooth arc-shaped semicircle knives to slot and remove the waste, paperboard get into slitting roller after slotting, slitting knives cut both sides of the paperboard neatly. (Note: pressing wheel and slitting knives are installed in same roller, convenient to adjust.

- Paperboard is sent out by six transmission shafts after slotting, corner-cutting, creasing and slitting. This machine power is equipped with the frequency speed controller (speed is adjustable freely), adopting JTE frequency converter.

- This machine adopts electric planetary gear phase adjustment to adjust the paperboard size, can adjust without stopping.

|

Technical Specifications |

|

|

Model |

CZL-1000 |

|

Machine max speed |

150pieces/min |

|

Max feeding size (L×W) |

1800mm×600mm |

|

Min feeding size (L×W) |

450mm×180mm |

|

Min slotting interval |

Negative knife (A×B) 150mm×50mm |

|

|

Positive knife (A×B) 80mm×80mm |

|

Min height of box (H) |

70mm |

|

Dimension (Length*Width*Height) including stacker |

3500mm×3600mm×1800mm |