ZH-880PFT

Pre-Folding Type Folder Gluer Machine

1. The machine is running steady with strengthened single side driving system, and it is also easy for maintenance.

2. The motor is controlled by a transducer (inverter) which is available for automatic timing. It is power saved and it helps to work stably.

3. Paper is feed by several thick belts under the help of vibration motor. Feeding is continuous, exact and automatic with this system.

4. Grinders are provided in both sides of machine, to make gluing more stable and firm.

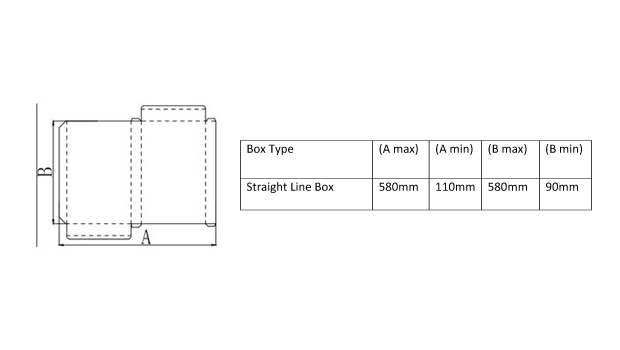

5. The machine is able to fold and glue straight line boxes. In the prefolding part, the first fold and the third fold can be at 180° and 90°.

6. The second fold and the fourth fold are molded at 180°. Options for 180°-135° in pre-folding part is available.

7. An infrared photoelectric control system is in this machine. Pressing unit and counter will work synchronously with the feeding speed. Machine will slow down and stop running when no sheet there. And it’s also able to reduce waste.

8. Small box like output size at 30mm is able to be done after the special design according to customer requirement.

| Technical Specifications | |

|---|---|

| Model | ZH-880PFT |

| Line speed | 0-180m/min, continuous adjustment |

| Usage paper | 250-500 g/ms, paperboard |

| Box forming | Straight line box |

| Fold method | 1st & 3rd folds 90o, 2nd & 4th folds 180o |

| Paper feeding | Automatic feeding, grinding unit |

| Electric power | 3.2 kw |

| Dimension | 9.0*1.2*1.5m |

| Weight | 2000kg |

| Condition | New |