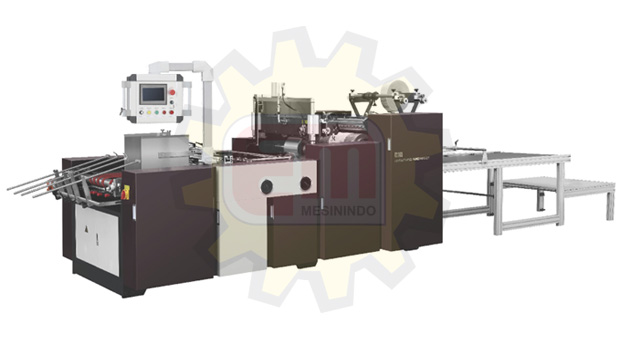

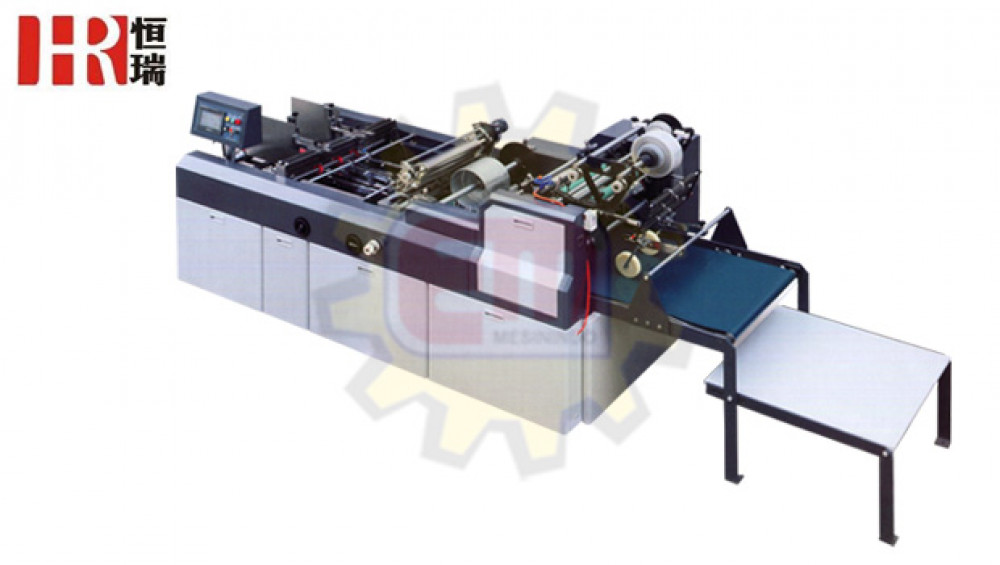

ZKT-700B

Window Patching Machine

The paper feeder is controlled by PLC with a human-computer interface. The length of paper to be fed can be entered on the touch screen, so that paper can be input quickly and accurately. Also, it applies to card paper and corrugated paper. The film feeder is controlled by a servo control system of a famous international brand. The length of film to be cut can be entered on the touch screen. Not only can film be cut accurately, but also adjustment can be made more quickly and directly. The film feeder is equipped with a magnetic powder clutch to control film tension. The gluer can be pulled out easily and cleaned conveniently. The film cutter has a device which can make free axial rotation to fit different window position, which help reduce the adjusting time and improve productivity significantly. Based on the original mechanism, the layout of each section of this product has been improved in order to reduce the adjusting time, so that it becomes more efficiency and friendly. ZKT-700B is widely used for 90 degrees of angle window samples, has the function of angle cutting and scoring.

|

Technical Specifications |

|

|

Model |

ZKT-700B |

|

Speed |

2000-4000 pcs/h |

|

Paper length |

120-700 mm |

|

Paper width |

200-690 mm |

|

Film length |

50-400 mm |

|

Film width |

30-400 mm |

|

Main power |

2.2 kw |

|

Power of pump |

1.5 kw |

|

External dimension |

4200 x 1400 x 1500 mm |

|

Weight |

2000 kg |